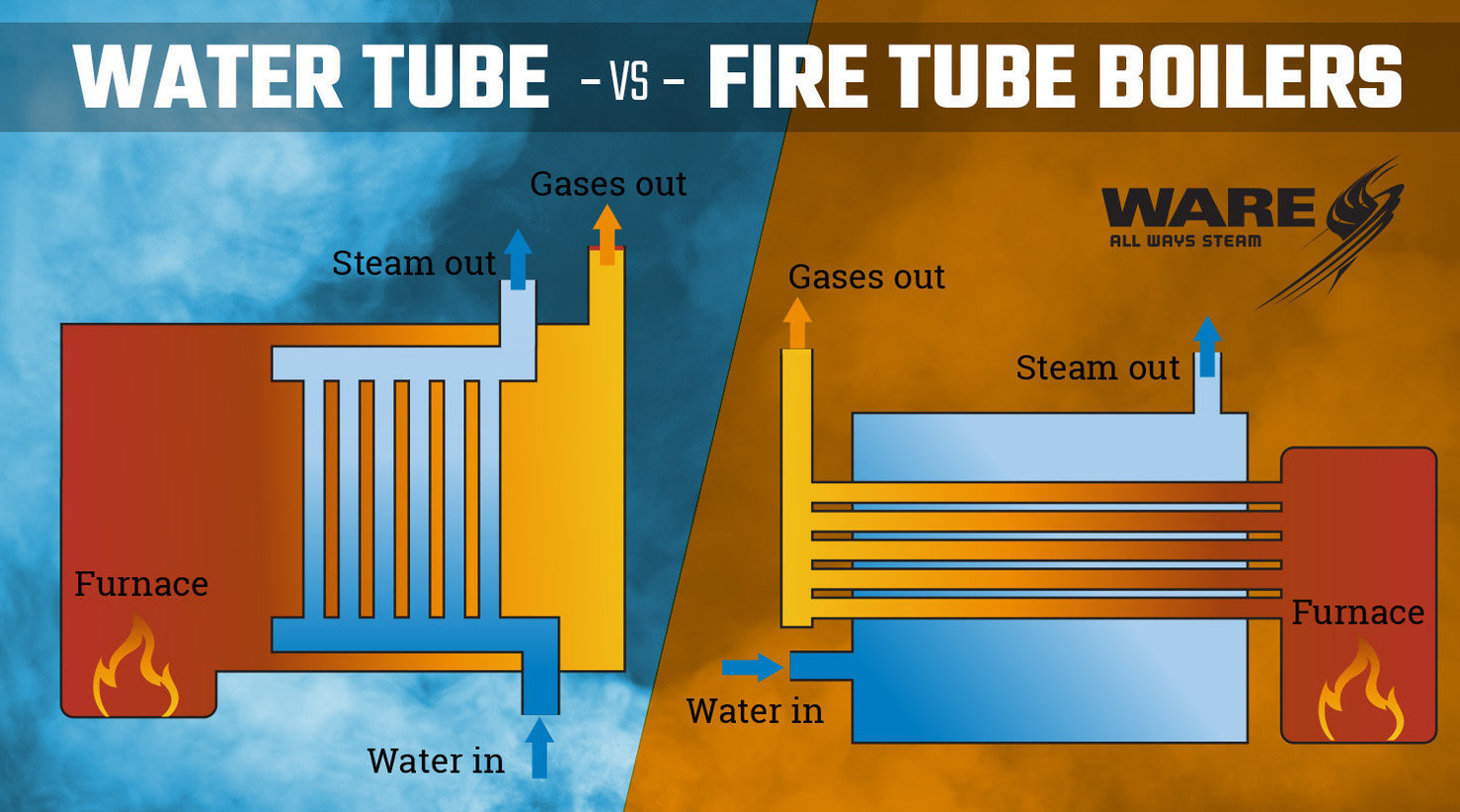

Inside every boiler out there, you’ll find a set of pipes that act as the transfer point between the boiler’s water supply and its heat supply. They’re the passages through which hot combustion gases or water flow so that heat from the fire side can make its way to the water side and, in so doing, create the steam that gets stuff done. But the type of tubes in your boiler depends on the type of boiler you’re operating.

TALK ABOUT TUBES

Before we get into specifics, let’s start with the basics. Tubes on a fire tube boiler are sheets of rolled metal that are several feet long, made of steel, located inside your boiler. They pass the length of the pressure vessel and are secured on each end (and often in the middle) by a plate of metal with multiple holes in it through which the tubes pass. This metal plate is called a “tube sheet”, and it’s integral to the operation of the boiler.

At first glance, the tube sheet looks like it’s all about structure and rigidity, keeping the tubes in place while they do their job. And to an extent, that’s part of it. But that’s not all of it. By keeping the tubes properly aligned and sealed, a tube sheet helps promote the most efficient movement of heat. Any misalignment in a boiler tube is going to cause leaks that will lead to boiler failure. While it may be minor, any boiler operator knows that a minor thing becomes a major thing over time. So thank your tube sheets for helping to preserve your efficiency and performance.

FIRE TUBES

A fire tube boiler is designed to work by passing hot gases through the tubes, which are surrounded by water. Those combustion gases may make several passes back and forth to squeeze every last bit of heat out of them before they head up the stack. If you’ve ever heard a boiler referred to as a “two-pass” or a “three-pass” boiler, that refers to the number of times the gases go back and forth.

For example, in a two-pass boiler, the gases will come out of the morrison tube, turn 180 degrees, and head through the tubes (which are surrounded by water) before going out the stack.

Fire tube boiler tubes tend to be anywhere from .095 to .135 inch. They need to be this thick because they have a lot of water pressure acting on them, not because of operating pressures. In fact, overall, fire tube boilers operate at lower temperatures and pressures than water tube boilers. They also tend to be larger than water tube boilers, because of the large amount of water surrounding the boiler tubes. Fire tube boilers also tend to have a lower steam generating capacity.

WATER TUBES

Water tube boilers operate the exact opposite from fire tube boilers. In a water tube boiler, water flows through tubes surrounded by hot gases, absorbing heat through the tube walls to make steam. Because the water is inside the tube rather than outside, water tube boiler tubes tend to be thinner than fire tube boiler tubes. But there are several other important differences. Although they tend to have thinner tubes, water tube boilers operate at higher pressures and temperatures, making them more suitable for larger industrial boilers that put out a lot of steam.

Water tube boilers also tend to operate with greater efficiency. This is due to the fact that the tubes are thinner, which allows more rapid heat transfer. It’s also due to the fact that there is less water in the tubes, compared to a fire tube boiler which has a tremendous amount of water surrounding the tubes. Since less water comes in contact with the heat overall, the water can heat faster. A smaller steam drum versus the large fire tube shell also means that the boiler can operate at a higher pressure, and get hotter than a fire tube boiler, allowing it to generate more steam per hour than its fire tube counterparts.

A FEW MORE DIFFERENCES

There are a few other differences between fire tube and water tube boilers that can help determine which is best for your operation. For example, water tube boilers heat up faster and can get up to full rate faster than fire tube boilers. Water tube boilers also tend to lose less heat per hour than fire tube boilers, which also contributes to their overall higher efficiency.

If you’re in the market for a new or rental boiler, the type of boiler you get will ultimately depend on the number and type of work processes you’re trying to accomplish. It’s best to get an expert involved when making that decision. Good thing the experts from WARE are standing by to help. We’re also here to help with anything else you need, from parts and supplies from our online BoilerWAREhouse to expert help with maintenance and service. Whatever you need, we’re here to help.