Every boiler is separated into two sides for a reason. Fire and water don’t play together very well. Keeping them apart is crucial to the performance, safety, and longevity of your boiler. That’s why WARE hydrostatic testing is so important. It detects obvious leaks, but can also detect leaks that may be too small to see, but could prove problematic in the near future.

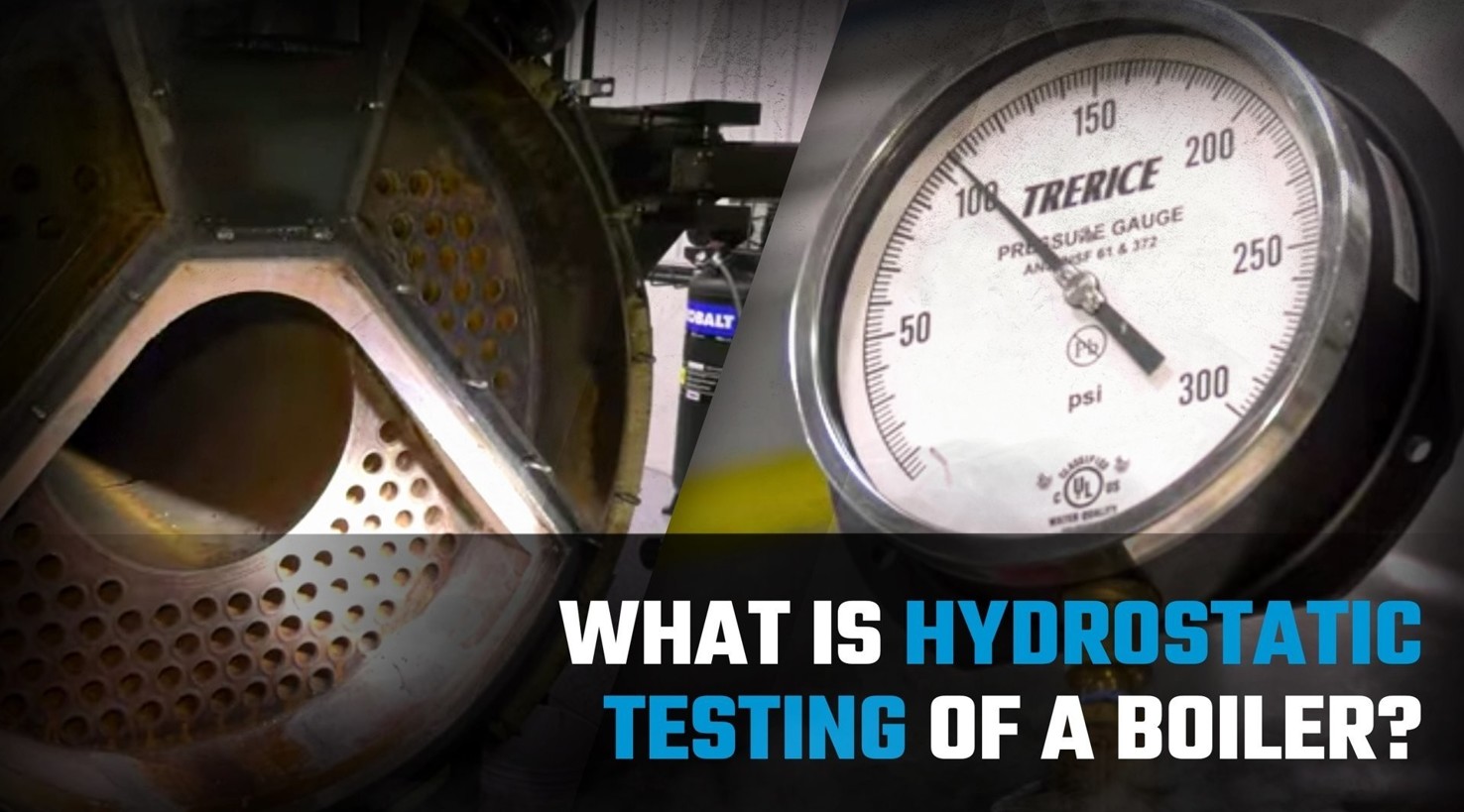

For a hydrostatic test to be performed, the fire side of the boiler must be open, and the tubes clearly visible. The water side of the boiler is first filled, then the feed pump is used to bring the boiler up to its typical operating pressure.

After any repair, the boiler may need to be tested at 1.5 times the maximum allowable working pressure using a smaller pump made for this process. In this case the relief valves will need to be temporarily removed for the test.

Once the water side is properly pressurized, the tubes are inspected for any leakage, seeping, or bulging. However, tiny cracks and leaks can be nearly invisible. That’s why the true test of the water side’s integrity is its ability to hold a specific pressure. Once the supply pump pressurizes the boiler to the correct level, the boiler is monitored for a half hour to make sure the pressure level doesn’t drop. If there’s no loss, there’s no leak, and the boiler passes the hydrostatic test.

If you’re ready to have your boiler hydrostatically tested to ensure optimal safety and performance, WARE technicians are standing by. Our technicians are experts in the service and maintenance of every kind of boiler out there, so let us know how we can help.