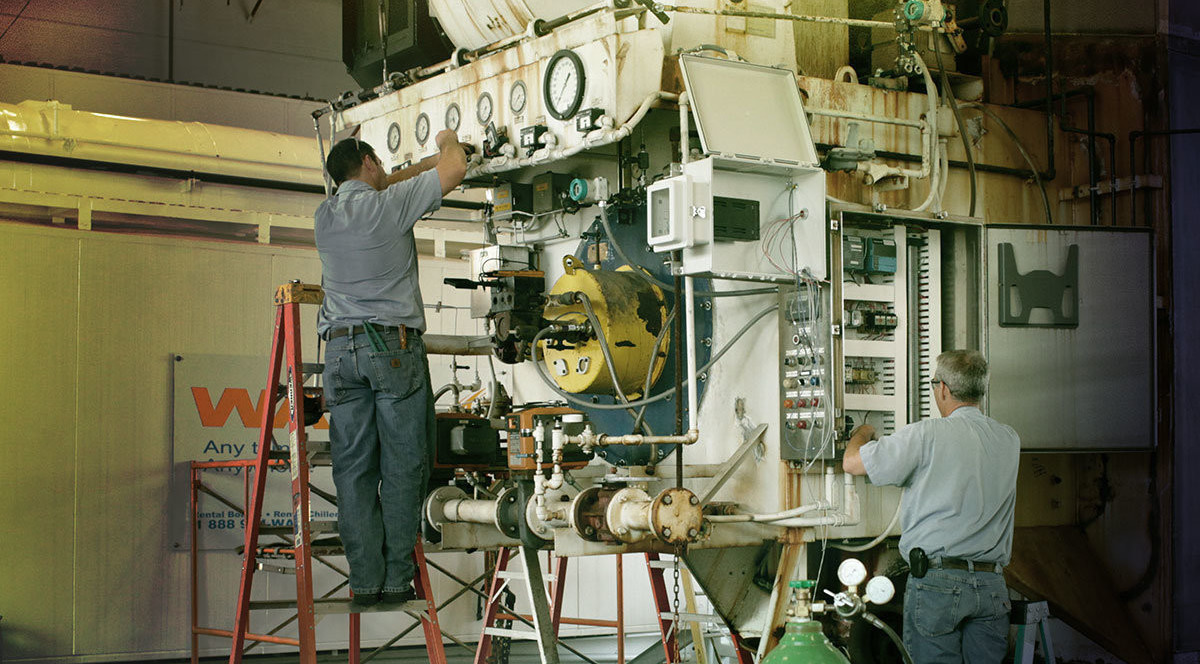

Now that peak heating season is behind us, many clients are tempted to let regular maintenance tasks take a back seat. When the sun is shining and the mercury is rising, it’s easy to forget all the hard work your boiler did for you during the icy-cold months. However, over the years we’ve found that if maintenance isn’t performed consistently, it can lead to costly repairs down the road.

That’s why we’ve put together a comprehensive checklist of maintenance tasks to help you keep your boiler running in peak condition and ready to handle the last cold snap of spring. We also invite you to visit our YouTube channel any time you need a refresher. These resources are totally free and available to you 24/7.

As you know, there’s more to owning a boiler than just firing it up when the temperature drops. Today let’s review a weekly boiler maintenance checklist, so you can be sure you’re keeping your system in top condition. Remember: Before you begin, it’s necessary to follow all manufacturer recommendations and government regulations regarding maintenance and inspections. It’s also highly recommended that you keep a logbook for maintenance tasks.

- Check that your main fuel valve is operational and that it closes when you turn the boiler off.

- Test this by turning your system off and listening for the valve to make contact. It should make an audible click when it closes.

- This is also a good time to check your meter gas. When the system is off and the valve is closed, the meter gas should stop, assuming the boiler is on a separate meter.

- Check the gauge glass to ensure it isn’t being etched by steam erosion.

- When the glass is etched, it will be cloudy instead of transparent. This is an early warning that the glass is becoming thin and needs to be replaced.

- Check the boiler motors and monitor their function for small changes.

- Test this by listening to the motors and training yourself to recognize changes in the way they sound.

- Unusual squeals, grinding noises or vibrations are reasons to seek professional assistance.

- It's important to check the low water cut-off and perform blowdown maintenance. Some boilers require daily blowdown maintenance, so make sure to follow your manufacturer's recommendation.Test this by draining the water out until the boiler shuts down, indicating the low water cut-off is functional.

- Check burner operation to ensure it’s functioning properly.

- Test the flame scanner to make sure it will shut down the boiler if the flame goes out. If you can’t access the flame scanner directly, shut off the main gas valve to test for functionality.

- Burners should shut down within four seconds of the signal to the flame scanner being interrupted.

- Check the combustion management and linkage system for tightness and accuracy.

- Make sure the boiler is modulating—going from low-fire to high-fire and back again.

- Check your entire system for leaks and inefficiencies.

- Any valve is subject to leakage and all will require maintenance eventually.

With the right maintenance program, you can save yourself time and money in the boiler room. Boiler equipment failures can be dangerous, so if you have any questions or concerns about maintaining your boiler, or you see something out of the ordinary, contact the boiler room pros at WARE.